Get automatic replenishment,

reduce wastage and

automate availability.

It's time to move from spreadsheets to smart automatic orders.

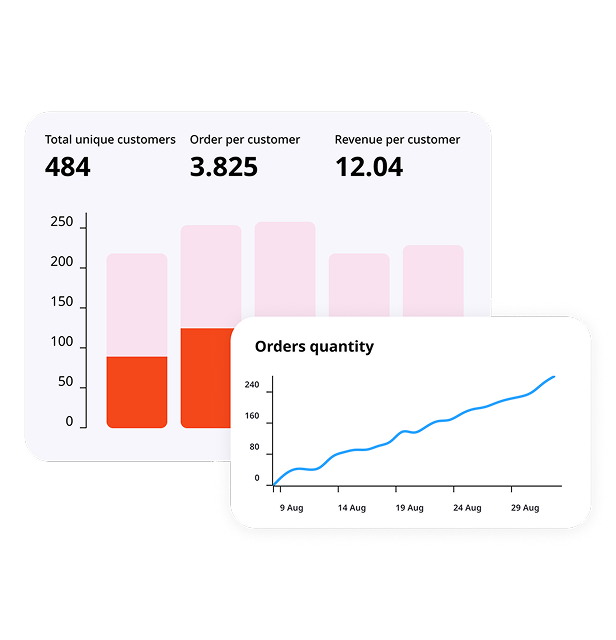

Never go out of stock

Get stock replenished when you need it, never lose a customer again.

Reduce waste

Stop draining your profits with wasted product.

Release deadstock

Improve turnover and raise capital.

Automate manual tasks

Avoid costly mistakes and automate everything with technology.

7%

Reduction in out-of-stock levels

1.4x

Turnover improvement

40%

Reduction in food waste

100%

Automated ordering

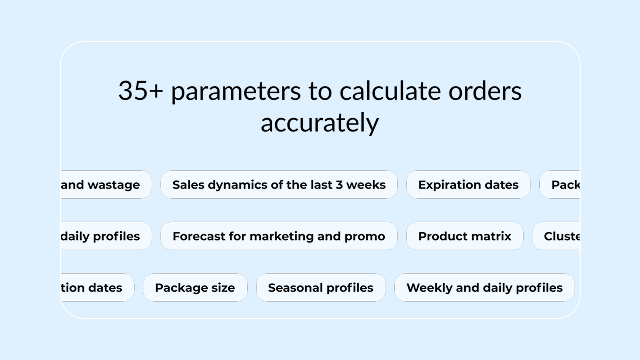

Calculate orders quickly and automatically with 35+ configurable parameters

Configure your settings and go.

-1.png?width=638&height=359&name=Image%20(2)-1.png)

Most of the work happens in the background

Our algorithm calculates orders automatically, only asking you to view simple alerts to make sure that everything is done correctly.

Save money, maximise resources

Autonomous order processing helps you effectively manage human resources, reducing unnecessary cost and maximising capacity.

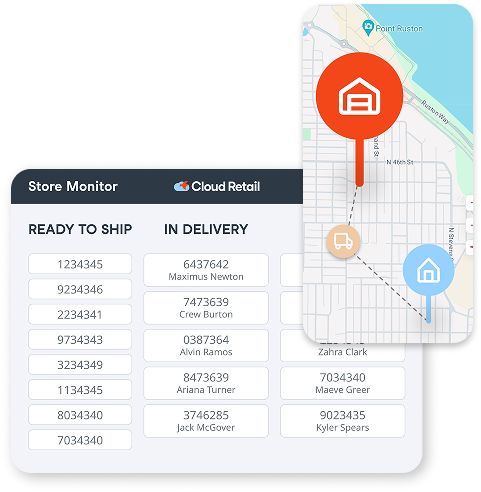

Supply chain management

anyone can use

Get full control over your inventory and ordering process. No analyst. We implement the maximum number of verifications and tooltips in our code, so anyone can do it.

Dynamic stock check

Make sure you always have the correct inventory levels, even if sales or schedule has changed

Forecast

Based on real sales without out of stock and outliers, to consider the real potential of each Store and SKU

Core Replenishment

Replenish using both pieces and packages levels

Smart alerts

Check alerts to improve core replenishment KPIs - reduce waste, improve turnover, avoid out of stock

Automate orders

Reduce the number of people engaged in replenishment by calculating 99% of orders automatically

Auto-increase orders

Automatically for upcoming promotional events or price reductions, always have enough inventory

Calculate transfers

Between stores to optimise inventory and reduce working capital

Check expiry dates

Take into account expiration dates to reduce write-offs

Book a demo

Let’s solve your biggest e-commerce challenges, today.

-2.png?width=86&height=86&name=Group%201948753875%20(4)-2.png)

-4.png?width=86&height=86&name=Group%201948753875%20(3)-4.png)

-Jul-09-2025-01-43-55-9055-PM.png?width=86&height=86&name=Group%201948753875%20(2)-Jul-09-2025-01-43-55-9055-PM.png)

-Jul-09-2025-03-08-57-5624-PM.png?width=86&height=86&name=Group%201948753875%20(2)-Jul-09-2025-03-08-57-5624-PM.png)

-Jul-09-2025-03-08-57-5809-PM.png?width=86&height=86&name=Group%201948753875%20(3)-Jul-09-2025-03-08-57-5809-PM.png)

-3.png?width=86&height=86&name=Group%201948753875%20(4)-3.png)

.png?width=86&height=86&name=Group%201948753875%20(5).png)

-Jul-09-2025-03-17-57-8132-PM.png?width=86&height=86&name=Group%201948753875%20(2)-Jul-09-2025-03-17-57-8132-PM.png)

-Jul-09-2025-03-17-57-8132-PM.png?width=86&height=86&name=Group%201948753875%20(3)-Jul-09-2025-03-17-57-8132-PM.png)